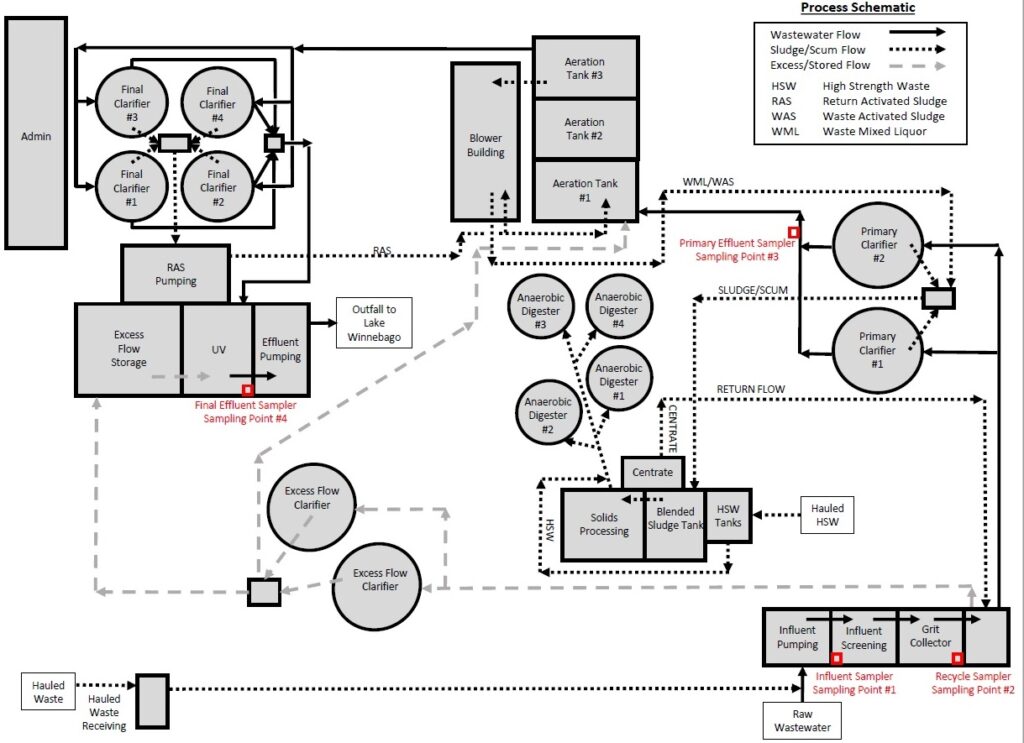

Wastewater enters the treatment facility through a 72″ main interceptor into a wet well. The wastewater is pumped up to the 2nd story of the building and from that point is gravity fed through the rest of the plant. On its way to preliminary treatment flow and pH are monitored to alert us of a potential plant upset.

Wastewater enters the treatment facility through a 72″ main interceptor into a wet well. The wastewater is pumped up to the 2nd story of the building and from that point is gravity fed through the rest of the plant. On its way to preliminary treatment flow and pH are monitored to alert us of a potential plant upset.

There are six submersible pumps ranging in capacities from 8-13.5 MGD. These pumps run automatically, utilizing variable frequency drives which allow them to ramp up and down to maintain a set level in the wet well.

There are six submersible pumps ranging in capacities from 8-13.5 MGD. These pumps run automatically, utilizing variable frequency drives which allow them to ramp up and down to maintain a set level in the wet well.

The first step in wastewater treatment is coarse or fine screening to remove large materials (rags, logs and other large objects) or small materials (food scraps) from the wastewater that could interfere with the treatment process.

The first step in wastewater treatment is coarse or fine screening to remove large materials (rags, logs and other large objects) or small materials (food scraps) from the wastewater that could interfere with the treatment process.

The next step is to remove smaller objects (such as sand, broken glass, silt and pebbles). If these objects are not removed, they can damage pumps and other mechanical devices. These objects also have a tendency to settle in corners and bends, thus reducing flow capacity and eventually clogging pipes and channels.

The next step is to remove smaller objects (such as sand, broken glass, silt and pebbles). If these objects are not removed, they can damage pumps and other mechanical devices. These objects also have a tendency to settle in corners and bends, thus reducing flow capacity and eventually clogging pipes and channels.

After screening the solids and removing the grit, the wastewater still contains light organic suspended solids. Some of these can be removed by gravity in a sedimentation tank. These tanks are typically twelve feet deep and hold the wastewater for two or three hours. What settles out is called sludge. The sludge is removed from the primary treatment tank with mechanical scrapers and pumps. Grease, oil, and other floating substances rise to the top, where they are removed by surface skimming equipment.

After screening the solids and removing the grit, the wastewater still contains light organic suspended solids. Some of these can be removed by gravity in a sedimentation tank. These tanks are typically twelve feet deep and hold the wastewater for two or three hours. What settles out is called sludge. The sludge is removed from the primary treatment tank with mechanical scrapers and pumps. Grease, oil, and other floating substances rise to the top, where they are removed by surface skimming equipment.

Secondary treatment removes soluble materials that require oxygen for decay, as well as further removal of suspended solids. Many of the excess nutrients in city wastewater, if not treated and dumped directly into streams, kill fish and other wildlife by depriving them of oxygen. These excess nutrients naturally rot, or decompose, on their own; but require oxygen to do so. They steal dissolved oxygen from the water as they decompose, and fish and other aquatic wildlife die from oxygen starvation.

The amount of these oxygen-stealing nutrients present in wastewater is measured in terms of biochemical oxygen demand (BOD, pronounced “bee-oh-dee”). BOD is the amount of oxygen, usually measured in milligrams of oxygen per liter of wastewater, required to decompose the organic nutrients found in the wastewater. Because these organic nutrients decompose on their own in the presence of oxygen and common microorganisms, they can be decomposed by merely forcing oxygen into the wastewater and giving them time to decompose by natural processes. This is the procedure used in secondary treatment.

Our activated sludge system is the first of two phases of secondary treatment and is where the majority of the nutrient removal takes place utilizing the nitrification and denitrification processes. We have three, 3-pass aeration basins. In these aeration basins we try to create the optimum environment for the microorganisms to thrive.

Our activated sludge system is the first of two phases of secondary treatment and is where the majority of the nutrient removal takes place utilizing the nitrification and denitrification processes. We have three, 3-pass aeration basins. In these aeration basins we try to create the optimum environment for the microorganisms to thrive.

The name “activated sludge” comes from the biological mass formed when oxygen (in the form of air) is continuously injected into the wastewater. In this process, microorganisms are thoroughly mixed with organics under conditions that stimulate their growth. As the microorganisms grow and are mixed by the agitation of the air, the individual microorganisms clump (or flocculate) together to form a mass of microbes called activated sludge.

About eight cubic feet of air are required for every cubic foot of wastewater. Once flow enters the aerobic zone the nitrification process begins by converting the ammonia to nitrate utilizing oxygen. This is all taking place below the surface as the mixed liquor serpentines its way through the basin.

Oxidation Reduction Potential (ORP) is used to measure the oxidation or reducing potential in the anoxic zone and this helps us know what kind of biological reactions are taking place in the basins and whether adjustments need to be made to change them.

We have an online ortho-phosphorus analyzer that monitors the level in our effluent continuously. It controls our chemical feed pumps and tells them when to turn on and what rate to dose at. It is a very helpful tool when talking about efficiency of operations.

Another way to remove phosphorus is utilizing biological phosphorus removal, (BPR). This is where an environment is created that encourages specific bacteria to grow and take up phosphorus instead of using chemicals. We are in the process of trying to create those types of conditions and benefit from biological removal and in turn save money on chemical usage.

Each has an anoxic zone that has little to no oxygen, biochemical oxygen demand (BOD) supply, and is regularly mixed by means of mechanical mixing. Each basin has an aerobic zone as well that has oxygen which is used by the microorganisms to breathe and also aids in mixing. The anoxic zones’ main impact takes place in the process of denitrification which converts nitrate to nitrogen gas which is released into the atmosphere. This takes place by way of a nitrate recycle pump pumping a portion of the oxygenated flow through the wall and back into the anoxic zone where the ample supply of BOD and lack of oxygen completes the conversion.

We monitor the dissolved oxygen content as well as oxidation/reduction potential (ORP). Maintaining a consistent dissolved oxygen level (DO) is crucial to a stable environment which encourages full treatment.

We monitor the dissolved oxygen content as well as oxidation/reduction potential (ORP). Maintaining a consistent dissolved oxygen level (DO) is crucial to a stable environment which encourages full treatment.

Once the primary effluent reaches our secondary treatment process it comes together with our return activated sludge (RAS) which we receive from our final clarifiers to help maintain a healthy and diverse environment of organisms within the system. This combined flow is known as mixed liquor.

We monitor the total suspended solids content of our mixed liquor to ensure the activated sludge process has enough structure and organisms to continue full treatment.